Nozzle is one of the most important components of a 3D printer. It is also critical to whether the 3D model can be printed successfully. If there is a problem with the nozzle of the 3D printer, we may not be able to print a perfect model and cause some problems, such as the heated filament does not go out of the nozzle, the first layer cannot be formed on the printer bed, the filament sticks to itself. To avoid these situations, we’d better check and clean the nozzle when we want to use the printer, and if the nozzle has been clogged, let’s see how to clean 3D printer nozzle.

Why Is PLA Not Coming Out of Nozzle? Is the Printer Nozzle Clogged?

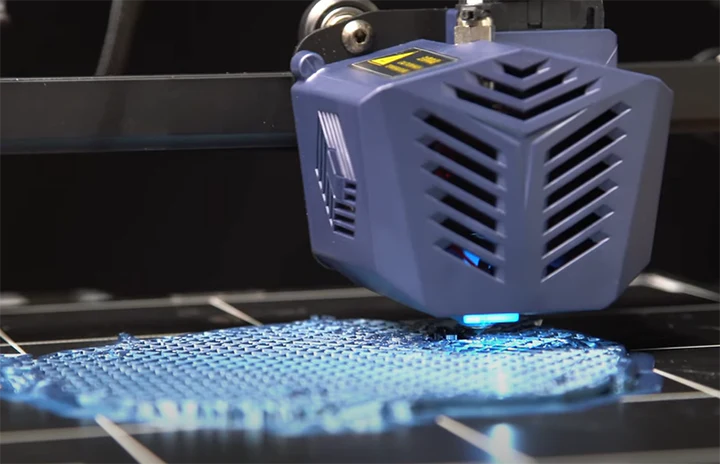

FDM is also known as Fused Deposition Modeling, FDM 3D printing works on this principle, which requires heating a material, such as PLA, at the hot end, extruding it through the nozzle, and reducing the digital model layer by layer to make it into a physical object.

So when we print the model, we need to make sure that the filament is extruded smoothly and that the PLA is properly formed on the printer bed when it is heated and passed through the nozzle. In this process, if the filament is melted at high temperatures but not quickly extruded from the nozzle, it is easy to cause clogging due to cooling and solidification, or the nozzle itself is clogged with foreign objects, which may also cause the PLA non-coming out of the nozzle.

When the filament cannot be squeezed out, the easiest way to check if the nozzle is clogged. We need to clean any material that may be left on the nozzle and see what is available in the tool box provided by the 3D printer manufacturers. Use the small brush to clean the nozzle, then stick a slender needle in the nozzle to unclog it.

Why the First Layer Not Stick On the Printer Bed?

However, when we keep the nozzle clean and check that there are no obvious problems with it, we can also check if the other parts are functioning properly.

- Position of filament, is the filament correctly inserted?

- Height of Z-axis, whether the Z-axis is too low, making the nozzle too close to printer bed?

- Extruder, can the filament be extruded smoothly?

Print Head Cleaning: 3 Methods to Help You Clean the Print Head

Method 1: Use the clean toolkit: brass wire brush, needle, wiping cloth

Raise the Z-axis to the proper height to ensure that the printer will not run and that the nozzle temperature will not burn you. Then use the prepared cleaning tools, clean up the external residue with a brass brush, use the thin needle to unclog the melted filament in the nozzle, and do a wipe with a cloth. That is a simple cleaning job to help the nozzle to keep clean, then it will be able to squeeze out the filament more smoothly.

Method 2: Cold pull, a way to clean the printer nozzle without any tool

Why should you how to cold pull? First of all, it is one of the best methods to help you clean the nozzle and deal with clogging problems. In addition, when you want to change the filament with different color or material, you can also use the cold pull to clean up the previous residue.

Step 1: Insert the filament into the port of the print head and set the temperature of the nozzle, according to the filament you use. For example, for PLA, we heat the nozzle temperature to 200°C, then wait for it to heat up and extrude some filament, about 20mm.

Step 2: Set the nozzle temperature to 90°C and clear the material that has been extruded. Once it reaches about 90°C, pull the filament out of the print head by hand. You can see that the filament being pulled out has an excess extension, and the residual debris in the nozzle will be brought out together.

Step 3: You can repeat the second step of the cold pull until the filament is pulled out without residual debris on it. Very well, this is the specific operation of the cold pull, I hope it will help you to clean the nozzle.

Tutorial video: How to clean the printer nozzle using cold pull

Method 3: Remove the nozzle from print head, clean it deeply or change a new one

If the nozzle clogging is more complicated, or the nozzle has adhered to the residual filament, the old debris is difficult to brush off, then we better remove the nozzle and consider whether it needs to be deep cleaned or even replaced with a new one. If the nozzle has been used for a long time, this is indeed a viable option.

First you need to remove the nozzle from the print head, preferably with the help of tools from the toolbox, heating the nozzle will also make it easier to remove. Then depending on the filament you are used to printing, we will suggest different ways to clean the printer nozzle.

- For PLA: you’d better get a torch and burn all the PLA off the nozzle.

- For ABS: acetone can effectively dissolve ABS filament. So put the nozzle into a cup with acetone and soak it for about 30 minutes. However, acetone has almost no effect on PLA cleaning.

Tutorial video: How to change a new nozzle on 3D printer

Have a Better Experience with Printing: Choose High-Quality Filament

Cleaning the nozzle is necessary, but some poor quality filaments can aggravate our work and make it frequent and even difficult. Therefore, we can pick more trustworthy products, a higher quality filament, to enhance our printing experience.

Why we choose Anycubic Filament? This filament is less prone to tangles, it has a neater spool that minimizes filament tangles and can ensure a smooth printing experience. Anycubic filament offers +-0.02mm precision and highly consistent colors to bring high quality 3D printing.

|

Anycubic Filament |

Other Filament |

|

Neat spool |

Disorder |

|

No tangle |

Tangle |

|

Print smoothly |

Nozzle blockage |

|

High success rate |

Failure |