Specially Developed for DLP 3D Printer

In September 2021, Anycubic Photon Ultra became the first consumer 3D printer with DLP technology in the industry. In 2022, Anycubic made an important leap in DLP technology, Anycubic Photon D2 came out. And this DLP Craftsman Resin is developed to take full advantage of its high-precision printing.

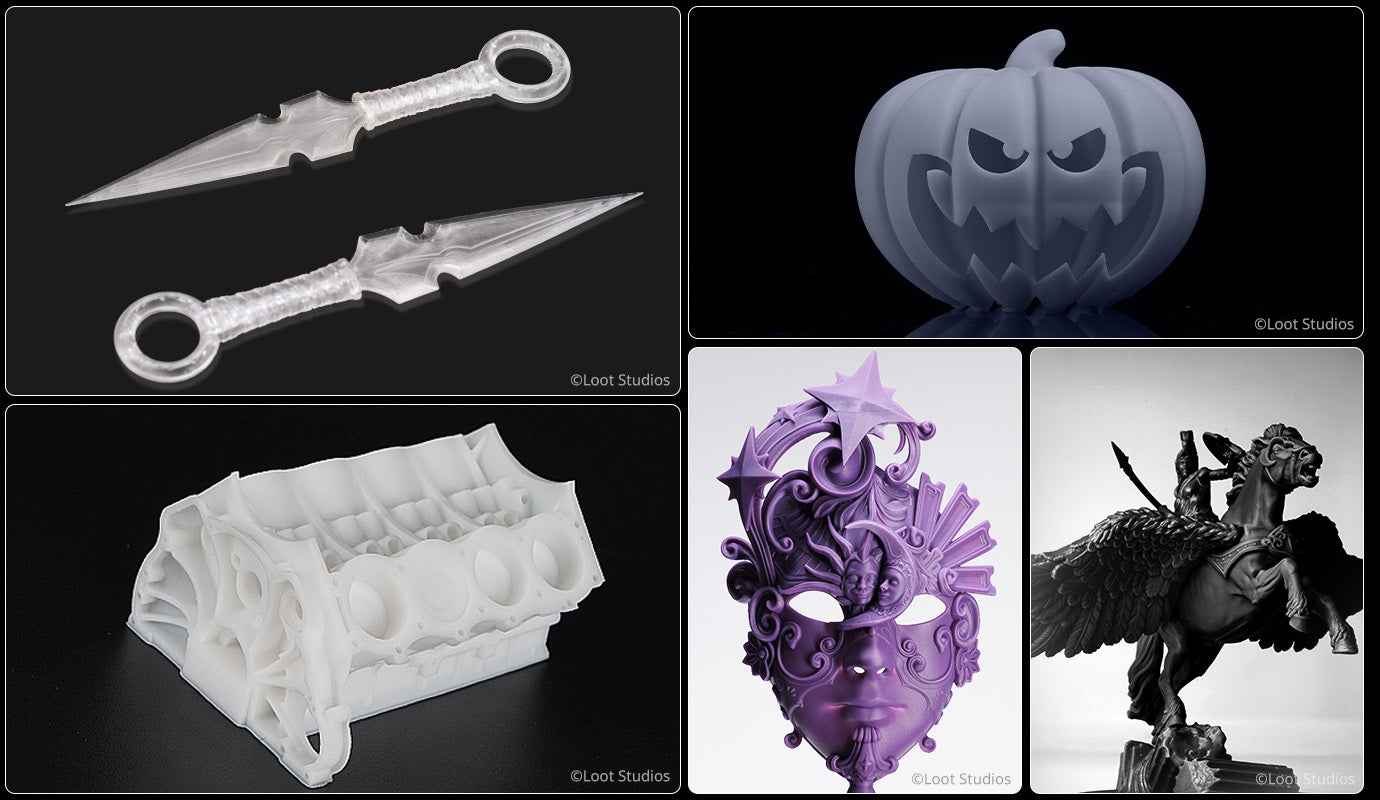

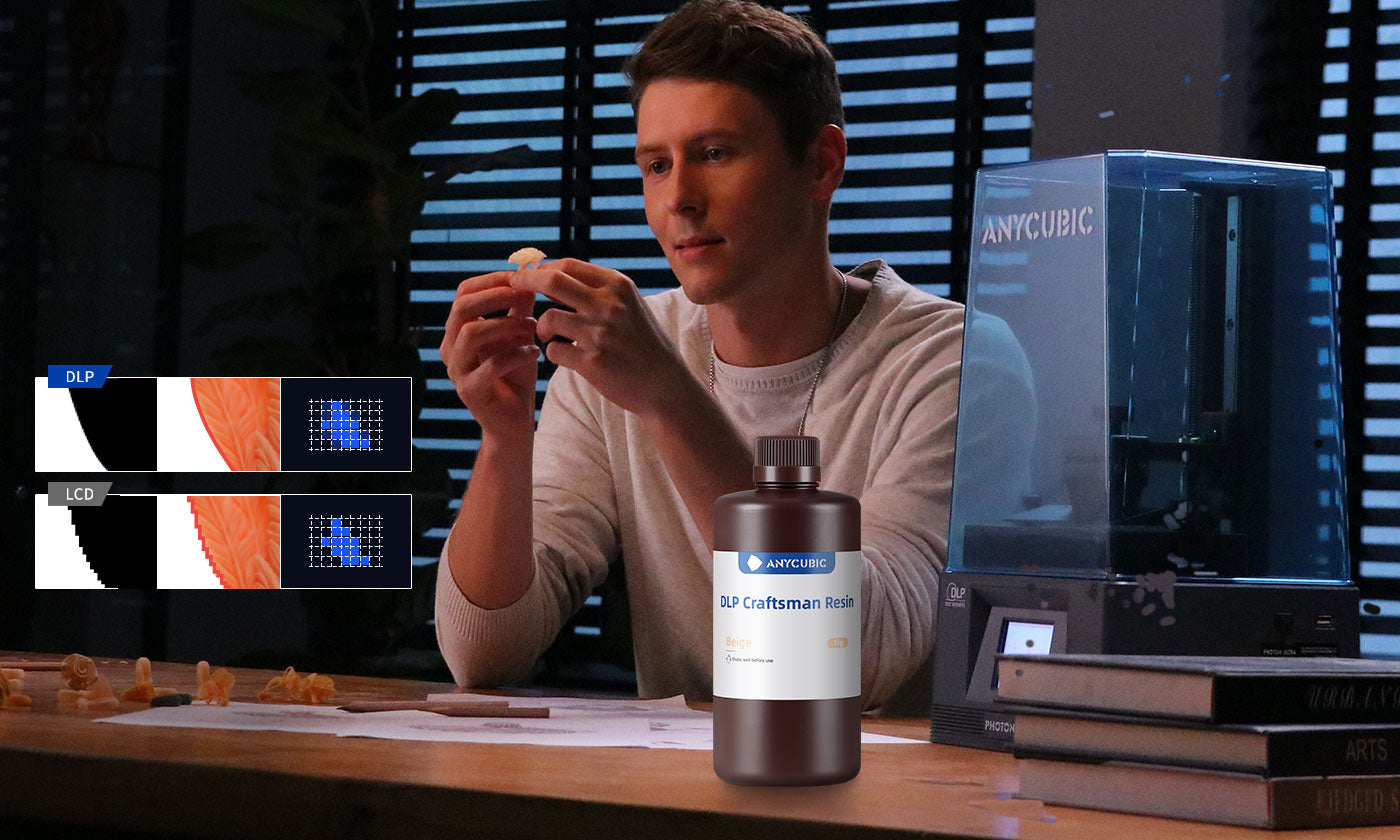

DLP Printing Deserves Better Resin

The precision benefits of DLP technology deserve better resins. When discussing 3D printing, most people focus on the resolution of 3D printers. But experienced makers know that the materials used are as important as the printer in order to make the final results look good.

Photosensitive Resin+ NanoCeramic

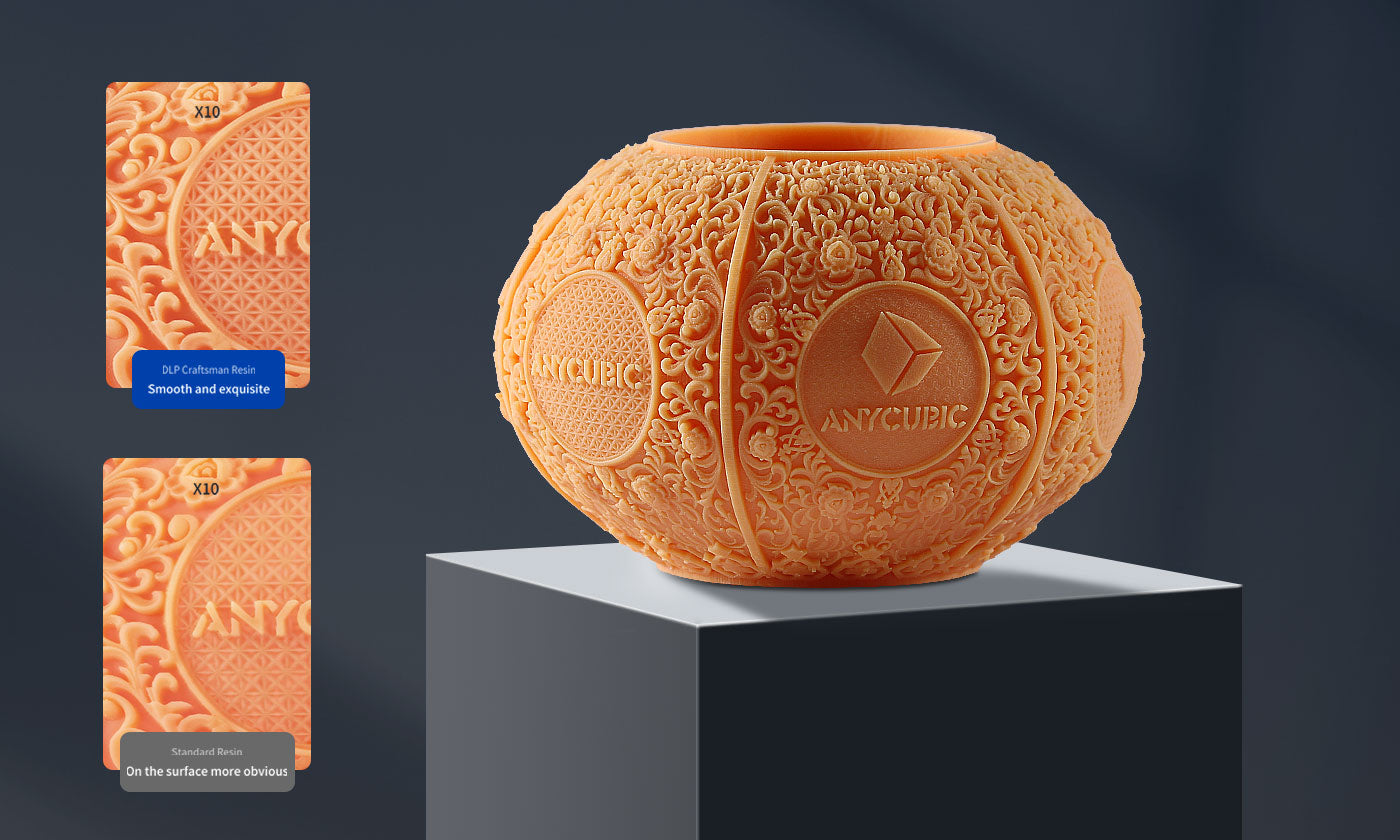

Anycubic developed this DLP Craftsman resin to help makers obtain more detailed 3D printed items. Nano - scale microcr - ystallineceramic powders are added, which enhances the scattering of light within the resin, making the resin more sensitive to light and curing finer. Ordinary resin--> layer lines DLP Craftsman resin-->smooth and exquisite

Extra Long Shelf Life

Other resin products on the market have a shelf life of only 1 year. Thanks to the upgrade of formula, the shelf life of Anycubic DLP Craftsman resin is up to one and a half years.

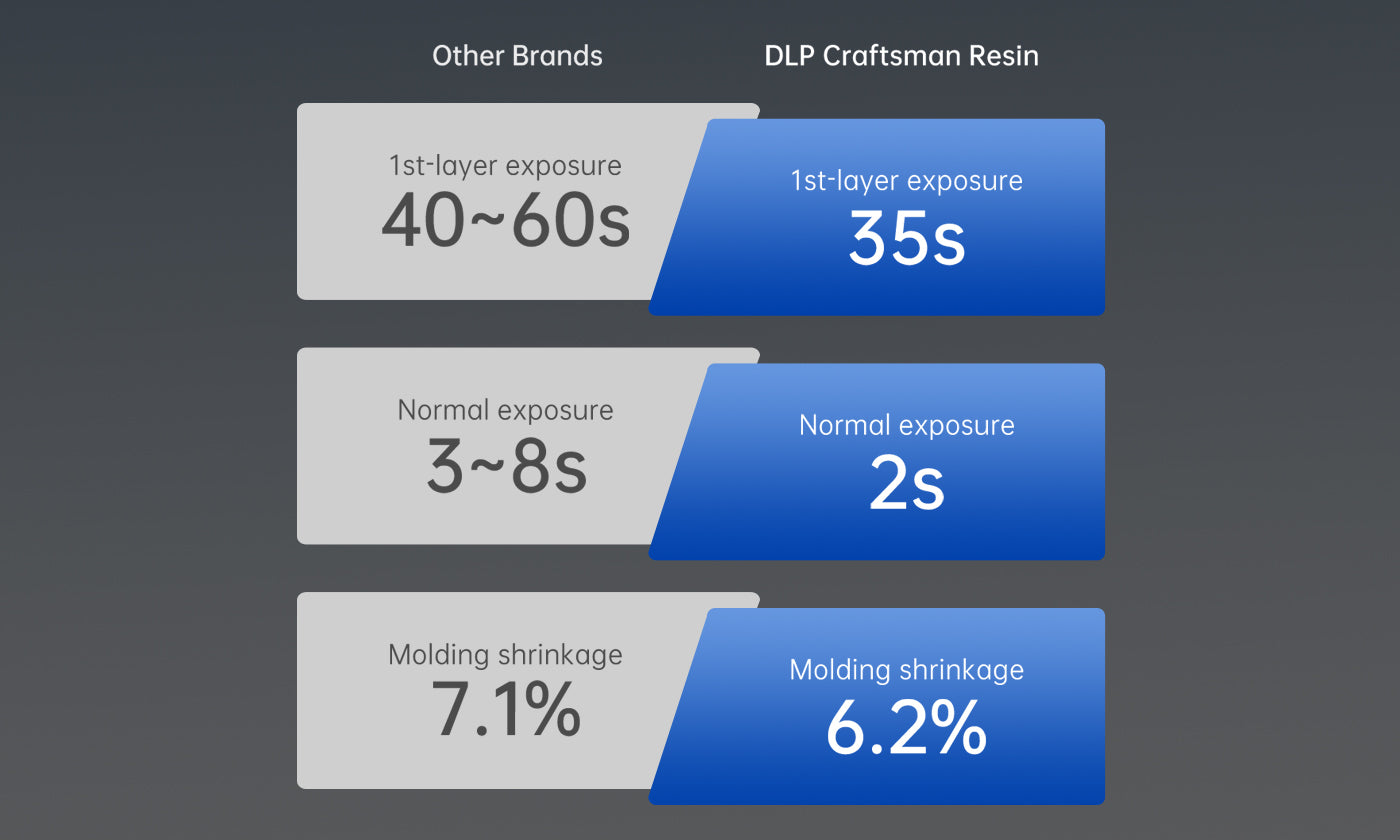

Fast Speed, Low Shrinkage

Also benefited from formula upgrade, Anycubic DLP Craftsman resin not only has high printing accuracy, long shelf life, and fast printing speed, low shrinkage rate. The first exposure time can be as fast as 35 seconds (much faster than 60 seconds of other brands), and the ordinary exposure can be as fast as 2 seconds per layer (much faster than 8 seconds of some competing products), which can save your 3D printing waiting time and significantly improve your work efficiency. Molding shrinkage as low as 3.7%, much less than some competing products of 7.1%. When cooled, thefinished print is not much different from when itwas just printed. What you see is what you get.

File Download

Recommended Printing Parameters

| Printer Model | Layer Thickness | Exposure Time | Light-Off Time | Bottom Exposure Time | Bottom Layers | Anti-Aliasing Level | Z Lift Distance | Z Lift Speed | Z Retract Speed |

| Photon M3 Premium | 0.05 mm | 2.5 s | 0.5 s | 25 s | 2 | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon M3 Max | 0.05 mm | 2 s | 2.5 s | 35 s | 6 | 1 | 8 mm | 3 mm/s | 4 mm/s |

| Photon M3 Plus | 0.05 mm | 2 s | 0.1 s | 23 s | 3 | 1 | 8 mm | 2 mm/s | 3 mm/s |

| Photon M3 | 0.05 mm | 2 s | 0.5 s | 23 s | 4 | 1 | 6 mm | 3 mm/s | 4 mm/s |

| Photon D2 | 0.05 mm | 2.5 s | 1 s | 28 s | 5 | 16 | 5 mm | 2 mm/s | 3 mm/s |

| Photon Ultra | 0.05 mm | 2 s | 1 s | 35 s | 4 | 4 | 6 mm | 5 mm/s | 2 mm/s |

| Photon Mono X 6K | 0.05 mm | 2.5 s | 0.5 s | 40 s | 8 | 1 | 8 mm | 2 mm/s | 3 mm/s |

| Photon Mono 4K | 0.05 mm | 2 s | 0.5 s | 40 s | 6 | 1 | 6 mm | 4 mm/s | 6 mm/s |

| Photon Mono X | 0.05 mm | 2 s | 0.5 s | 30 s | 8 | 1 | 8 mm | 4 mm/s | 4 mm/s |

| Photon Mono | 0.05 mm | 2.5 s | 0.5 s | 40 s | 6 | 1 | 6 mm | 4 mm/s | 6 mm/s |

Color Type

Instructions for Use

1. Before use:

Shake the liquid resin before use;Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

2. When using:

Unscrew the cap and add it to the resin tank according to the equipment requirements; Select the correct print parameters and settings for printing.

3. After use:

After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol(≥95%), lactate or isopropyl alcohol cleaning solution;

4. Post-processing steps:

(1) Remove the printed model from the molding platform with a blade;

(2) Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then takenout and drained; ANYCUBlC Wash & Cure machines are suggested to ensure better effect.

(3) Proper processing, such as removing support, polishing, coloring, etc.

Precautions

1. The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

2. Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 60°C).

3. If the resin pigment settles, it can be used after stirring or shaking.

4. In order to ensure the performance of the resin, please take out the model in time after cleaning to avoid the model soaking in water for a long time.

5. To ensure the mechanical properties of the model, please perform post-curing in time after cleaning and drying.

To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing. Therefore, the following steps are recommended:

(1) The intensity of mercury lamp or Led light source is 5-10mW/m?, and the duration is no more than 1 hour (self-regulation);

(2) The exposure time in the sun (summer) is around 1 hour;

(3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited.

(4) lt is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive material.

Ps: Material properties willvary depending on the molding equipment, post-curing method and testing equipment. For safetyinformationplease refer to the MSDS of this product. lf you encounter any problems while using, please feel free to contact us.