Ways to Obtain Anycubic Filament Spools

1. Purchase Anycubic's reusable spools.

2. Reuse your previous spools.

3. Print your own spool from Makeronline.

Stronger Adhesion

The special surface treatment on the cool plate offers PLA filaments extremely strong adhesion at just 45°C. Effectively decreases the possibilities of warping and bottom layer separation when printing smaller parts and large-scale models.

Vibrant Colors

A vast selection of colors opens up more possibilities for creativity and your next project.

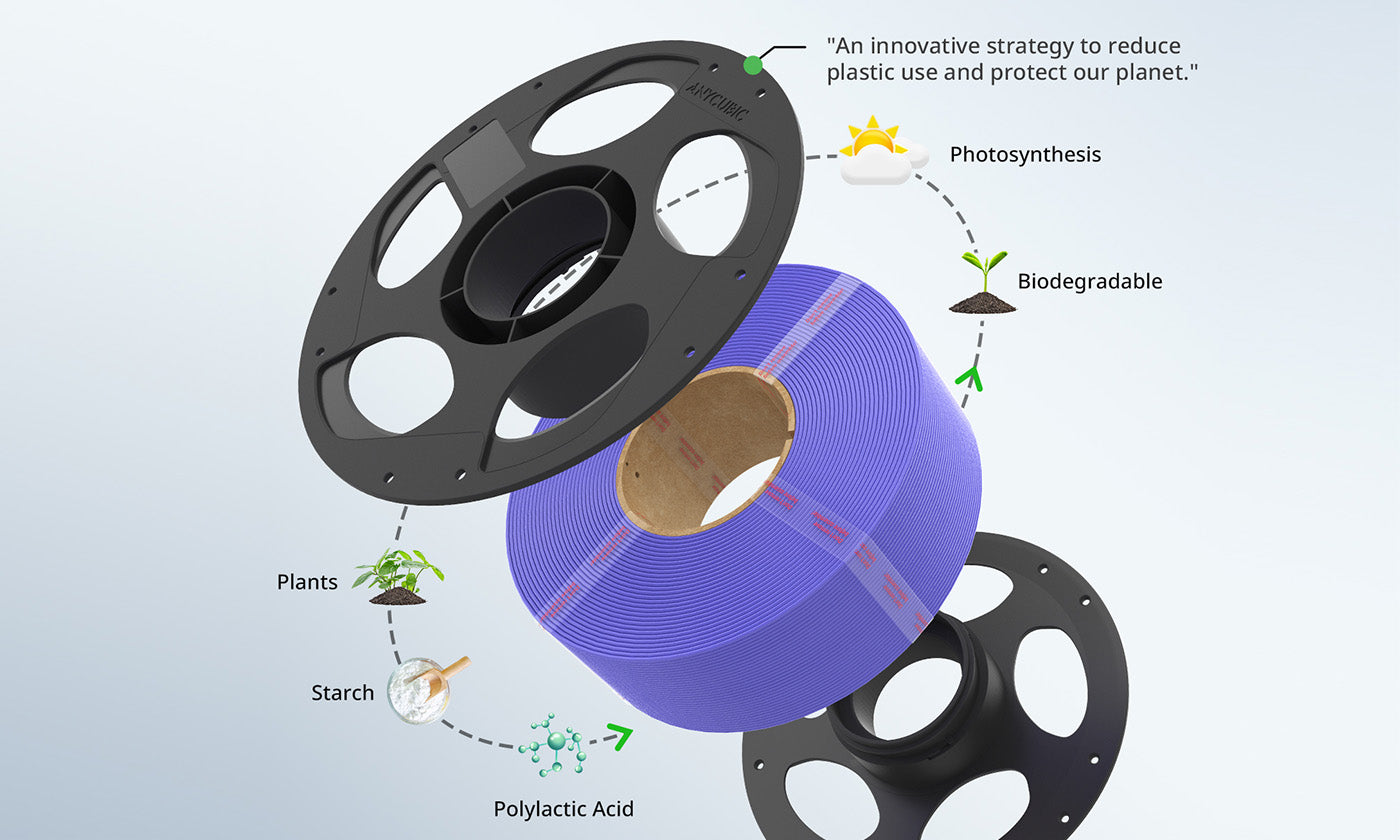

PLA Basic Refill Filament Characteristic

Boosting Efficiency with Intelligent Identification

The filaments feature intelligent identification chips that integrate seamlessly with the ACE Pro, allowing for automatic identification of printing information and enhancing the printing experience.

*The intelligent identification feature requires an internet connection and Anycubic-brand intelligent identification-compatible filaments.

Filament Installation

1. Label the Filament

2. Load the Filament

3. Locking the Spool