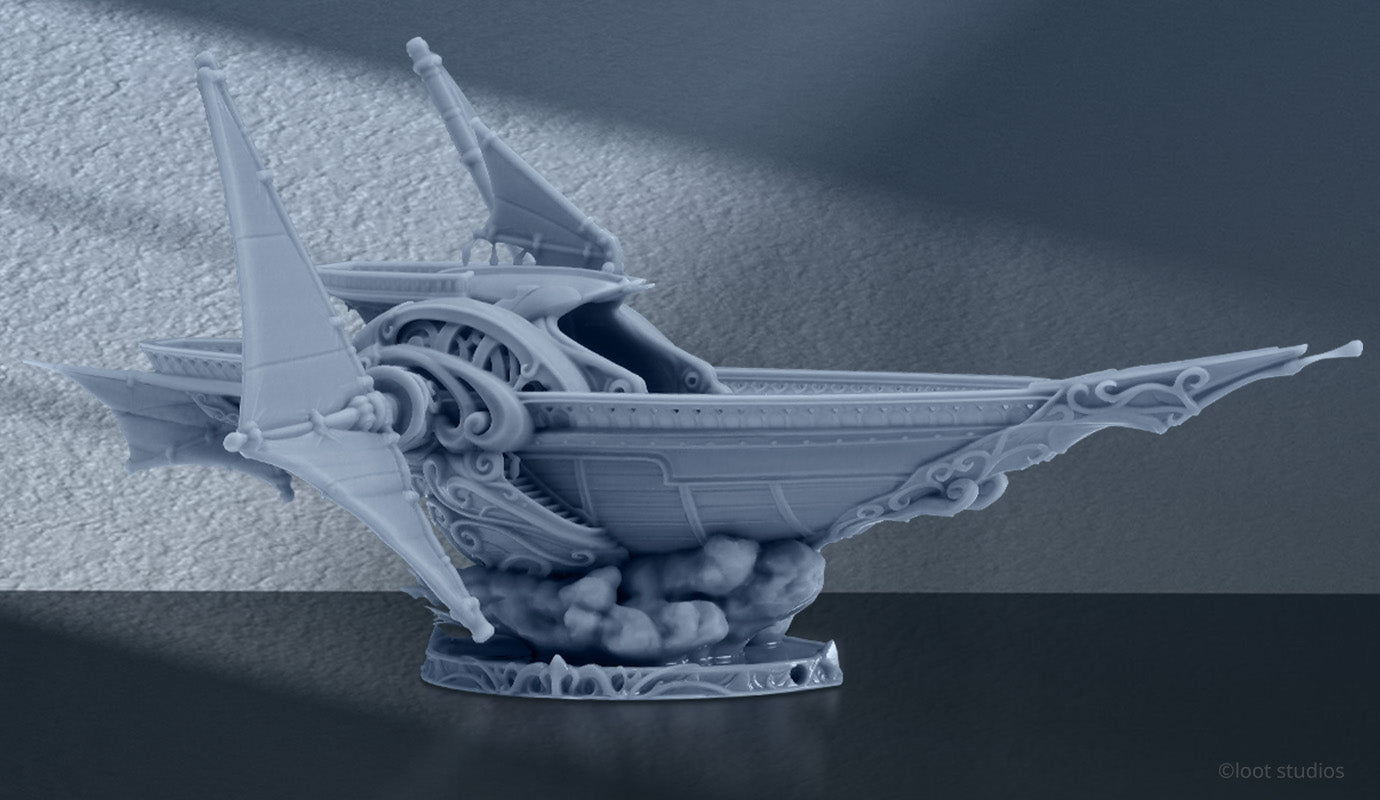

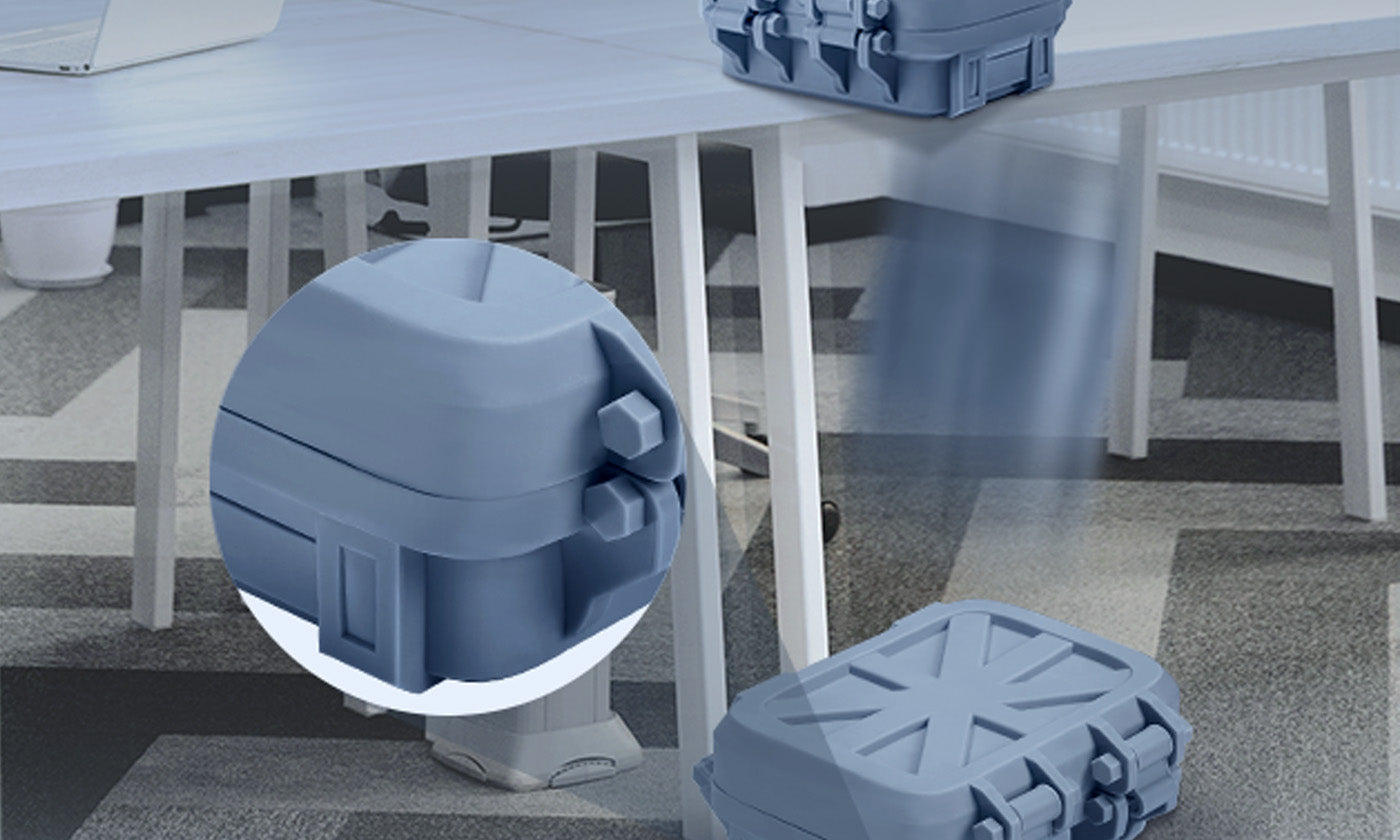

Excellent Toughness, Durability and Well-Performance

With its high toughness, strength, and impact resistance, the Anycubic Water-wash ABS-like Resin V2 is good for printing structural parts, tools, and other models that demand high performance. The printed models are suitable for drilling and tapping.

Easy to Post-Process

Low viscosity and high fluidity facilitate cleanability and accommodate different cleaning methods like water, washing machine, and ultrasonic, catering to diverse scenarios. The cleaned model has a nonsticky surface, and the support is easier to remove. making post-processing less challenging.

Durability

The final model shows excellent resistance to drops guaranteeing stability and durability. Moreover the model's durability is enhanced. The printed model can endure exposure to the natural environment for a year without cracks after proper cleaning and curing.

High Precision Minimal Shrinkage

With lower shrinkage, the risk of distortion and deformation is reduced, resulting in high molding accuracy and detailed models.

Low-odor

The mild scent reduces discomfort for those sensitive to odors creating a more comfortable printing environment.

File Download

Resin Parameters

Recommended Printing Parameters

| Printer Model | Layer Thickness | Exposure Time | Light-Off Time | Bottom Exposure Time | Anti-Aliasing Level | Z Lift Distance | Z Lift Speed | Z Retract Speed |

| Photon Mono M7 Max | 0.05 mm | 2 s | 0.5 s | 30 s | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M7 Pro | 0.05 mm | 1.8 s | 0.5 s | 25 s | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M7 Pro | 0.1 mm | 3.6 s | 0.5 s | 35 s | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M7 | 0.05 mm | 2.2 s | 1 s | 35 s | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono 4 Ultra | 0.05 mm | 2.6 s | 1s | 30 s | 1 | 5 mm | 8 mm/s | 8 mm/s |

| Photon Mono 4 | 0.05 mm | 2.8 s | 1 s | 30 s | 1 | 6 mm | 4 mm/s | 6 mm/s |

| Photon Mono M5s Pro | 0.05 mm | 4.2 s | 0.5 s | 35 s | 1 | 5 mm | 20 mm/s | 20 mm/s |

| Photon Mono M5s | 0.05 mm | 2.8 s | 0.5 s | 25 s | 1 | 8 mm | 6 mm/s | 6 mm/s |

| Photon Mono M5s | 0.1 mm | 3.2 s | 0.5 s | 25 s | 1 | 5 mm | 20 mm/s | 20 mm/s |

| Photon Mono M5 | 0.05 mm | 2.8 s | 0.5 s | 25 s | 1 | 8 mm | 6 mm/s | 6 mm/s |

Color Type

Instructions for Use

1. Before use:

Shake the liquid resin before use;Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

2. When using:

Unscrew the cap and add it to the resin tank according to the equipment requirements; Select the correct print parameters and settings for printing.

3. After use:

After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol(≥95%), lactate or isopropyl alcohol cleaning solution;

4. Post-processing steps:

(1) Remove the printed model from the molding platform with a blade;

(2) Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then takenout and drained; ANYCUBlC Wash & Cure machines are suggested to ensure better effect.

(3) Proper processing, such as removing support, polishing, coloring, etc.

Precautions

1. The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

2. Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 60°C).

3. If the resin pigment settles, it can be used after stirring or shaking.

4. In order to ensure the performance of the resin, please take out the model in time after cleaning to avoid the model soaking in water for a long time.

5. To ensure the mechanical properties of the model, please perform post-curing in time after cleaning and drying.

To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing. Therefore, the following steps are recommended:

(1) The intensity of mercury lamp or Led light source is 5-10mW/m?, and the duration is no more than 1 hour (self-regulation);

(2) The exposure time in the sun (summer) is around 1 hour;

(3) Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited.

(4) lt is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive material.

Ps: Material properties willvary depending on the molding equipment, post-curing method and testing equipment. For safetyinformationplease refer to the MSDS of this product. lf you encounter any problems while using, please feel free to contact us.