Desktop FDM printers can make our daily life very interesting, turning a digital model into an actual object in just a few hours. But when we use FDM 3D printers, we usually encounter some problems. Understanding how FDM printers work and the simple structure of the machine can help us quickly locate problems and solve problems encountered in the 3D printing process. Today we mainly introduce the print head of the desktop FDM printer, including the related extrusion system, cold end, hot end, etc. What is a print head, how does a 3D print head work, how to clean the print head, these practical information will help you improve the success rate of FDM printing.

What is a Printing Head in FDM 3D Printing?

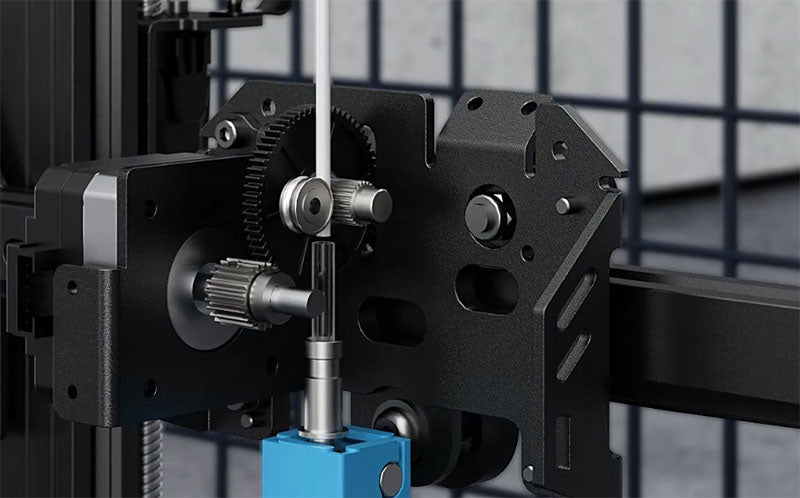

The extrusion system of the FDM printer consists of two parts, the cold end and the hot end. The cold end includes the motor and the extruder, which is responsible for the extrusion and withdrawal of the filament, it belongs to the power part. The hot end includes heat sink, fan, and nozzle, which are responsible for heating and cooling the material.

There are two types of extrusion systems commonly used in FDM printers, Bowden extruders and direct extruders. For example, the entry-level FDM printer Anycubic Kobra Neo is equipped with a direct extruder. The cold end is fixed on the hot end, and the filament is directly pushed into the hot end, which moves with the hot end during the printing process. The whole module here is the print head of FDM printer. It can control the extrusion of the material very well, and complete the heating and printing of the filament in the nozzle part.

How Does a 3D Print Head Work?

In the direct extrusion system, the cold end is directly fixed on the hot end, the filament is sent to the hot end through the extruder, and then heated through the nozzle with a temperature above 190 °C, the filament is melted at high temperature, and follows the printing head moving together, print from point to surface on the print bed, and then build up the model layer by layer. In this case, the weight of the print head is heavier than that of the cold-end and hot-end separation printing. The vibration of the cold-end motor is also added to the print head, so in theory, these extra weight and vibrations will affect the movement of the print head, and even cause the printing speed to slow down or the accuracy of the X-axis movement to gradually decrease.

There are also some cost-effective desktop FDM printers, such as the Anycubic Kobra Go, which is equipped with a Bowden extruder with separated hot and cold end, also known as a remote extrusion system. The cold end is fixed on the left side of the x-axis and rises and falls with the x-axis. The reduced weight of the print head and less interference from motor vibrations give the hot end an advantage in motion control accuracy and speed. When printing, the filament reaches the hot end through the Teflon tube, the nozzle of the print head continuously heats the conveyed material. Then the moving print head accumulates the melted filament on the printing bed layer by layer, and the construction of the entire model is such an action will repeat until the printing is complete.

Print Head Cleaning: How to Clean 3D Printer Nozzle and Prevent Clogs

3D printers are generally composed of many small and complex parts, so proper maintenance and calibration are especially important for the proper use of FDM 3D printers and to help us maintain accurate and high quality prints. How should we maintain this part of the print head? What should we do if we encounter clogging problems?

Usually, it is the nozzle part of the print head that is more likely to encounter clogging problems. The temperature of the nozzle is as high as 190-230°C during the printing process, which needs to continuously heat and melt the filament. If you do not pay attention to the cleaning of the nozzle, it is easy to cause clogging, which will have a great negative impact on the subsequent model printing. But the cleaning of the nozzle is also relatively easy and can be done with the help of simple tools.

There are two types of nozzle clogging, one is internal clogging and the other is external clogging. Internal blockage is generally caused by carbonization of consumables at high temperature for a long time, and it needs to be dredged after heating. External blockage is generally caused by platform changes. When the platform is not kept parallel to the nozzle, external blockage will be caused.

For more information on nozzle clogging and how to solve it, see 3 Methods to Fix Clogged Printer Nozzle